Here you can find news and interesting information

Tips, trends, dates: Keramischer OFENBAU has a lot to report.

At this point we set topics that have a lasting effect.

News everywhere

reliable competence

reliable competence

A fun fact about this pioneering project: Some of our team members not only worked on the new CO2-free „eTO“, but also on its gas-fuelled predecessor. Our recipe for success: Just the right mix of reliable competence, efficiency and innovation. To achieve this, know-how transfer is particularly important to us.

We are of course particularly proud of this innovative plant, which is paving the way for the ceramics industry into a more sustainable era. The Roca Group and LAUFEN Austria are exactly the right partners for this bold and pioneering project.

Many thanks for the successful collaboration!

🎊 HAPPY HOLI

🎊 HAPPY HOLI

The Keramischer OFENBAU team wishes you a happy holi!

Let’s celebrate the beginning of spring together, let’s forgive our past errors, put all conflict aside and start fresh!

This festival is a great reminder to not only allow all the colours in our lives, but to perceive, embrace and take them in fully. May they bring joy, happiness, success, and all you wish for into your life!

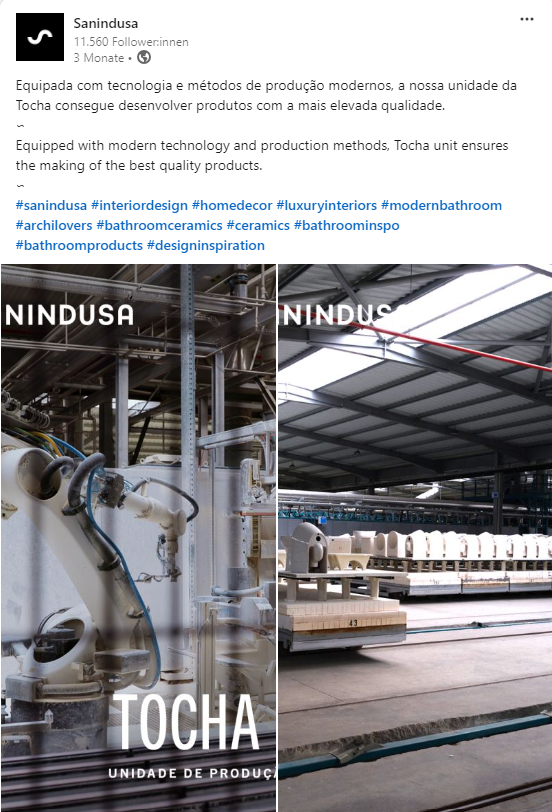

Top quality ceramics from maximum efficiency kiln

Top quality ceramics from a maximum efficiency kiln – we’re proud to be doing our part in this project, Sanindusa.

Thank you for your trust in our team!

📌 Save the date: Meet our experts at ceramitec 2024 in Munich, April 09-12!

Let’s talk about your kiln of the future: We have successfully implemented not only market leading energy efficiency in gas heated ceramic kilns, but also in electric kilns producing maximum quality ceramics and even up to 100 % hydrogen heating!

Get in touch and meet us at ceramitec in Munich for more on our roller, tunnel, and shuttles kilns for your technical and structural ceramics, your sanitary- and tableware, fuel cells and solid-state batteries.

We’re looking forward to this exciting event!

When? April 09-12 2024

Where? A5.322, ceramitec Munich

Merry Christmas from Keramischer OFENBAU

Merry Christmas from Keramischer OFENBAU

„Christmas is not a time nor a season, but a state of mind. To cherish peace and goodwill, to be plenteous in mercy, is to have the spirit of Christmas“ – Calvin Coolidge

With this in mind, we wish you a peaceful Christmas with your loved ones. Enjoy this wonderful time of the year and have a great start into a new and successful year 2024.

The end of the year is an exciting time: looking back at what was and looking forward with curiosity to what lies ahead. Thank you to everyone joining us on our journey, to all partners, customers, and all interested. We look forward to the new year 2024 with you!

Busy exhibition in Vietnam

💪 busy days at ASEAN Ceramics in Vietnam

Our booth in Hanoi has been buzzing with interested visitors ever since the exhibition opened yesterday. We’re glad to be presenting our portfolio, our competences, and innovative ideas together with ECT-KEMA GmbH.

Want to get more information? Take your last chance to visit our booth tomorrow and talk to our experts!

hall 2

lounge 3

booth A7

First electric tunnel kiln for sanitaryware

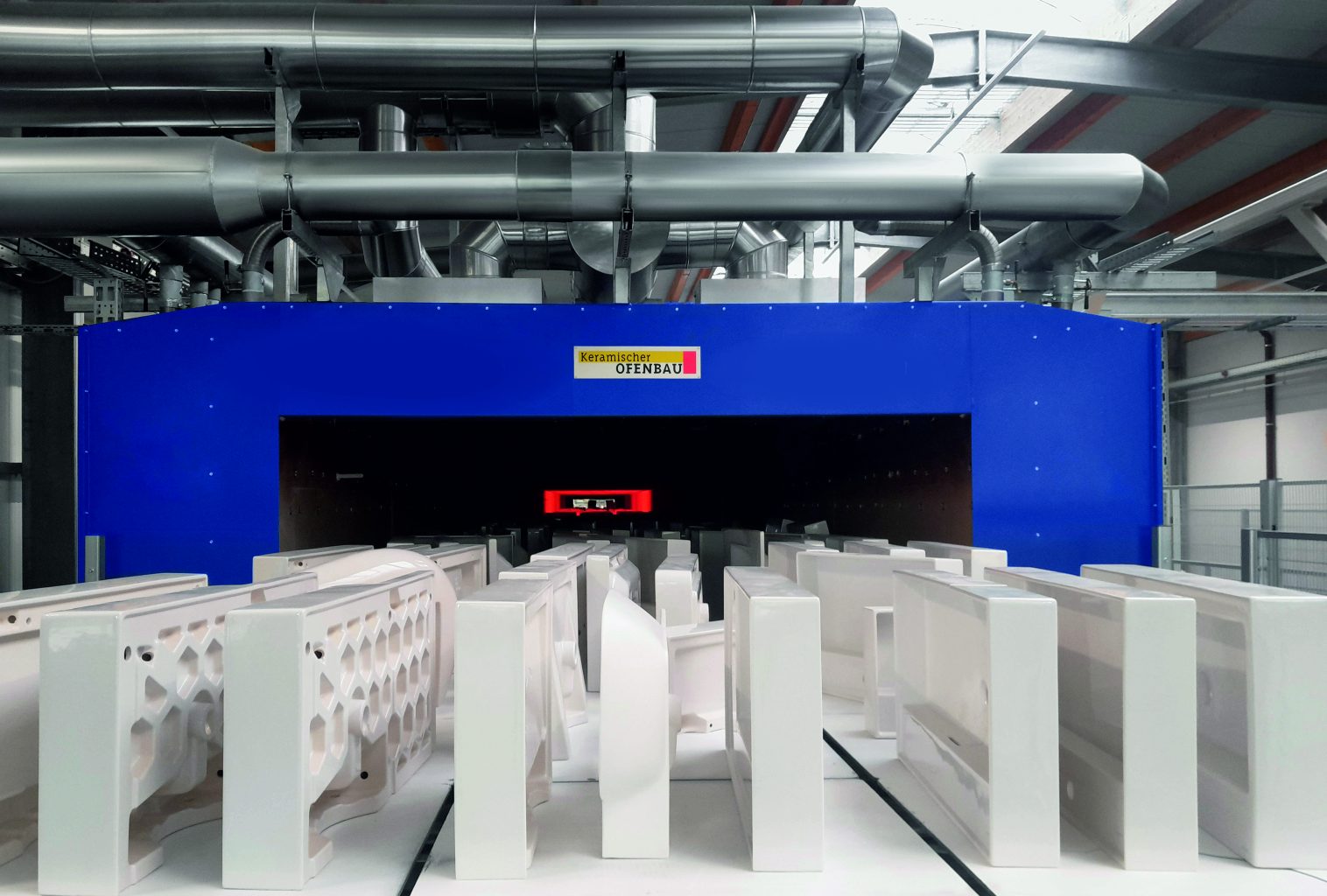

❗ First electric tunnel kiln for sanitaryware – made by Keramischer OFENBAU

We are proud to announce that our latest innovation – the world’s first electric tunnel kiln for sanitaryware – has successfully started production. With our technology innovation, we can now finally show you what we’ve created to aid in the net-zero production plans of LAUFEN Bathrooms and Roca Group.

Our project combines Germany, Spain, and Austria into one joint European success story on future-proofing an entire industry. What an awesome opportunity!

Our electric tunnel kiln will transform the ceramic industry with efficiency, reliability, and maximum quality. An important step towards the sustainable kiln of the future and the decarbonised ceramic industry. Let’s strengthen the industry and work towards our joint goal:

Find out more on this project in this article and check out this video.

Any questions left? Get in touch and talk to our experts!

Our kilns for your structural ceramics

💡 Our kilns for your structural ceramics

Ceramic products from our highly efficient kilns cross your way every day – directly as well as indirectly. Your roof is likely clad with tiles, your wall built with bricks from one of our kilns.

structural ceramics by Keramischer OFENBAU

And our customers from over 50 countries worldwide know: We are a reliable, competent and innovative partner on the way towards the kiln of the future. Producing maximum quality ceramics economically while minimising energy consumption. What sounds like a major challenge is what we’re best at!

Check out our portfolio for more information. We’re also looking forward to meeting you at ASEAN Ceramics in Hanoi!

Exhibition in Vietnam

Exhibition in Vietnam – talk to our experts!

German engineering – tailor-made for your ceramic production

Visit us at ASEAN Ceramics from November 28th to 30th! With our partner ECT-KEMA GmbH, we will be available for interesting talks on tomorrow’s ceramics at booth A7.

Our joint mission: Constantly proving and improving our customised solutions for your sustainable and efficient ceramic production. Together for the industry of the future!

From high-performing extrusion with ECT-KEMA GmbH to highly efficient and reliable firing with Keramischer OFENBAU GmbH kilns – get to know your potential with our solutions and talk to our experts in Vietnam.

We’re looking forward to your visit at our booth!

Hanoi Vietnam

ICE International Centre for Exhibitors

Hall 2

Lounge 3

Booth A7

28 – 30 Novembre 2023

Shubh Deepavali

🕯 Shubh Deepavali

The Keramischer OFENBAU team wishes all our trusted partners a wonderful and enlightening Diwali 2023!

May this festivity spread peace, joy, happiness, and health. Thank you to all our international partners, customers, and our Keramischer OFENBAU India-Team for the pleasant and successful partnerships!

Enjoy these special days!

Company tour in Hildesheim

📌 Company tour in Hildesheim

Our success worldwide benefits from global partners as well as a strong local network. As the 2023 winner of the Lower Saxony Foreign Trade Award, we have proven our expertise, success and importance.

That’s one of the reasons for yesterday’s visit to our premises in Hildesheim: The city’s Head Mayor Dr. Ingo Meyer and Wolfram Fischer, Head of Economic Development and Real Estate, joined us for a lively exchange on many interesting topics.

Apart from general interest in our company, our team, our export strategy and processes, we have also dived deep into the latest topics for a strong future. With our expertise, innovations and long-standing focus on efficiency, we are the ideal reference for future-proofing the industry. Alternative heat sources were thus a central talking point: How do we decarbonise via electrification or the use of hydrogen? How can we use these technologies locally? How can we best use local networks for effective exchange, know how, and mutual support? And of course, attracting even more expertise and highly qualified personnel to our city was discussed intensely.

Great conversations, lively exchange, and a positive outlook – thank you for your visit and the interesting talks! The Keramischer OFENBAU team is looking forward to the next visit and company tour!

Our kilns for your sanitaryware production

Producing sanitaryware in Keramischer OFENBAU kilns – a guarantor for outstanding quality ceramics fired with maximum efficiency.

Check out some of our many references in sanitary ceramics. Our reliable efficient kilns are tailored to specific needs: Continuous or not, a Keramischer OFENBAU kiln allows for maximum efficiency and reliability. Our competent team designs and builds kilns that leave no need unmet. Energy savings of up to 50 %? Heating with electricity or hydrogen? Our Keramischer OFENBAU team makes it happen.

Visit our portfolio or get in touch with our experts for more information on our shuttle, roller, and tunnel kilns for your sanitaryware production!

Meet us at ASEAN ceramics in Vietnam

Meet our experts!

The Keramischer OFENBAU team is thrilled and looking forward to meeting you in Hanoi in November. Interested? Get in touch and learn more about our highly efficient kilns and retrofit solutions for your existing one!

Table- or sanitaryware, technical or structural ceramics, fuel cells or solid-state batteries: We pave the way for maximum efficiency and quality in the thermal treatment of your ceramic product. Our experienced team finds the ideal solution for your specific needs.

We will push the limits towards your kiln of the future: Efficient, reliable and heated with your energy source of choice. Electric, gas, or hydrogen? We make it possible. You prefer a hybrid solution? That’s no problem for us.

Meet us at A7, ASEAN Ceramics, November 28-30 in Hanoi, Vietnam. We’re looking forward to talk about our portfolio, our solutions, and your benefits!

Our team at the Hydrogen

Our team at the Hydrogen Technology Expo Europe in Bremen

The kiln of the future comes from Hildesheim – as we have already repeatedly proven. Axel Krause, Thomas Alten and Georg von Oldershausen are therefore successfully visiting the Bremen Hydrogen Technology Expo and demonstrating: Our kilns can not only be heated with up to 100 % hydrogen. We also build highly efficient kiln systems for the thermal treatment of SOFCs and SOECs.

Roller, tunnel oder shuttle kiln; gas, electric or hydrogen heating: Our tailor-made solutions with product tracking and full automation maximise output and quality for large-scale fuel cell production.

How efficient can we be? On less than 700 m² we can currently realise up to 200 MW SOFC/SOEC production capacity per year – including adjacent infrastructure! These figures speak for themselves. Interested? Our team is always at your disposal. Together for the kiln of the future!

Home office for office dogs?

❓ Home office for office dogs?

Our team includes not only two-legged colleagues, but of course some four-legged ones as well. This also finds resonance in Germany’s oldest daily newspaper.

We have previously presented our department of office dogs here on LinkedIn as well. Milow, Leo, Merlin and Kira provide cross-departmental support in the areas of motivation, stress management, team spirit and exercise on the job. And as Anne Zumhasch explains in an interview with the Hildesheimer Allgemeine Zeitung: When one of the four-legged staff is on home office duty, it stands out. The question „Who authorized that?“ is then almost a matter of etiquette.

Of course, not only office dogs „work“ at our location in Hildesheim. Especially our teams in export, construction management and commissioning are looking forward to energetic support from new colleagues. And if you would like to become an industrial clerk, you’ve come to the right place.

You can find more information on our careers page. We’re looking forward to getting in contact with you!

New apprentice at Keramischer OFENBAU

New apprentice at Keramischer OFENBAU

Valuable addition to our team: Jannis Artelt is starting his apprenticeship with us to become a technical product designer for machine and plant design.

new apprentice for apprenticeship technical product design at Keramischer OFENBAU

We are looking forward to supporting Jannis through an exciting and eventful training program towards our future together. And of course we are curious to hear about the innovative ideas of our ambitious new colleague.

With our hands-on and broad-based vocational training concept and his instructor Marc Pengel, we’ve created a solid foundation for a successful time together.

All the best wishes from the entire Keramischer OFENBAU team! Welcome to the team, here’s to a great and fruitful time together!

You can find more information on apprenticeships with our team here for example. And check out our LinkedIn-Profil for more!

Talks for the future

Talks for the future 💡

Our systems are always ahead of the times – our focus has long been on developing particularly energy-efficient and future-proof industrial kilns for our customers. And we are also intensely driving forward the ceramic industry’s gradual move away from fossil fuels.

However, converting existing plants to hydrogen operation with our EnerViT H2 ready requires, in addition to our proven technologies, one thing above all: sufficient hydrogen for production.

This is of course a topic for MP Bernd Westphal as the spokesman for economy and energy policy. So we’re delighted to have had such a constructive exchange on the topic with him here in Hildesheim!

The potential of hydrogen in the ceramics industry is indisputable. To achieve decarbonized production of everyday items such as plates, bricks or sanitary ceramics, we must all work together – for an industry that is fit for the future.

Are you interested in more information about ceramic production with hydrogen – thanks to our EnerViT highly efficient as well? Contact our experts for a personal conversation! Our focus is on the future. Therefore, we not only offer the most efficient industrial kilns running on hydrogen. We also develop the optimal concept for every need. Whether electrically operated ceramic kilns or maximum efficiency – we are the ideal partner for your long-term success.

If you would like to help shape the future of the ceramic industry, feel free to visit our careers page. We look forward to hearing from you!

Customised solutions: hanging firing

❓ Unconventional requirements?

❗ We are the right people to talk to!

We are experts for customised solutions. That’s why we put our heart and soul into tailoring a kiln system to meet your every need. And if your ceramic product has to be fired in a hanging position? Then, of course, we also make hanging firing possible!

Competence, efficiency and innovation – that is the mixture we use to match the optimum kiln to each product. Alternatively heated, special requirements in production or new products such as SOCs: we make it possible. And always with maximum efficiency in mind.

Any questions? We will be happy to advise you!

You can reach our competent team by email at . For more information, please visit our website or our LinkedIn profile!

Of course, tailor-made solutions can only be offered by a highly trained team in which many years of experience are passed on and constantly expanded. Would you like to become part of it? Find out more about our current vacancies here. With our future-oriented energy-efficient kilns, we are in great demand – so our team is looking forward to your competent support!

Customised solutions for any need – we are your partner from the idea until production!

Summer greetings from Hildesheim

Summer greetings from Hildesheim

The PV system on the roof of our headquarters in Hildesheim is diligently producing the energy we can now gather thanks to great weather. With the temperatures of the last few days, things may be moving a little slower for once, but it’s good to be in our cooler offices. And when vacation weather comes to us, everything is a little more fun 🔅

The Keramischer OFENBAU team wishes all partners, customers and interested parties pleasant summer days!

Outside, temperatures climb above 30° C – but in our kilns, of course, it gets even hotter: at up to 1,800° C, sanitary or tableware ceramics, fuel cell components or building ceramics burn there. And highly efficiently of course. Because that’s what we’re particularly good at! More information is available on our LinkedIn profile, here on our website and at . Get in contact!

Summer greetings from Hildesheim!

Hydrogen for the ceramics industry

❓Hydrogen as an option for the ceramics industry?

💡Our take: YES!

We have been aware of it for quite some time: the ceramics industry must find and use alternatives to fossil fuels for the industry’s future and energy transition actions. Both ecological and economical factors make this the only sensible solution. And we see two strong options here: 1️⃣ Electrifying new plants and 2️⃣ alternative gases in existing plants.

Our partner Forschungsinstitut für Glas | Keramik has published their take on hydrogen in the ceramics industry here. And we have also thought about it intesively! Hydrogen for the ceramics industry?

Hydrogen for the ceramics industry?

Electrifying existing kiln plants is rarely a reasonable approach. We see a high potential for the use of (green) hydrogen in these cases. We already offer kilns and modernizations today that are not only highly efficient but allow for the use of up to 💯% already. Save energy and utilize innovation – that’s the ceramic industry’s future!

Transitional solutions are necessary until the industry’s energy needs can be fully met by renewable energy sources – making a defossilization possible. We offer high flexibility in this transition with our EnerViT H2 ready (flexibly using N-gas or hydrogen) as well as with hybrid plants that can even be operated with electricity produced on site.

We need to set the base for a sustainable future now. Find more information on our offer for a decarbonized ceramics industry here and here on our website.

Keramischer OFENBAU in Germany’s oldest daily newspaper

We’re all not always aware of how each and every one of us comes into contact with products from our kilns every day. Whether directly, with a ceramic cup in hand, or indirectly through high-voltage insulators – the probability that a ceramic object comes from one of our kilns is quite high.

And that’s a good thing! After all, we have been writing the goal of the more sustainable kiln of the future on our flags for many years now. Low-threshold through energy modernisation H2 ready or profound through the new construction of highly efficient electric plants – we are actively shaping the ceramics industry.

Would you like to support us? Click here for #vacancies we would love to fill with team players like you!

Keramischer OFENBAU in Germany’s oldest daily newspaper: We really deserve this. Many thanks to Tarek Abu Ajamieh for visiting us and for the great company portrait!

Find out more about the Hildesheimer Allgemeine Zeitung here.

Kilns of the future at aktiv-online

A great article about us, our team and our strengths in aktiv-online!

We are proud to deliver reliable performance even in difficult times and are especially pleased that this does not just stay in our bubble. In addition to the recognition from the Lower Saxony Ministry of Economics, Transport, Building and Digitalisation, the interest from many directions in our successes of recent years is a great confirmation of our work.

Our kilns for the ceramics industry of the future – we have been successfully pursuing this goal for years. New products and energy sources with maximum efficiency? We are exactly the right people for that. More information is available on our website here or here and of course on our LinkedIn profile.

Energy efficiency, new energy sources, digitalisation and the challenge of finding skilled workers – read more in the aktiv-online article. For this article, Werner Fricke visited us in Hildesheim and conducted an exciting interview with our team. You can find the result here!

Hildesheim partnerships – a strong base

What a great event!

Our team was represented by Anne Zumhasch and Thomas Alten, who enjoyed exciting presentations, valuable exchanges and many forward-looking conversations. Unternehmer Hildesheim e.V. once again put on a great event that showed us once again that our #Hildesheimat is exactly the right base for us.

image: Unternehmer Hildesheim e.V.

From Hildesheim to the world – that is our strength. A great team, strong partners, expertise and a lot of fun with the kiln of the future!

image: Unternehmer Hildesheim e.V.

We always stay in contact – of course, not only with political personalities like Olaf Lies, but also with other partners and participants of the Unternehmer Forum 2023. This is just as important as a strong location, strong partnerships and a strong team.

Burger barbeque with the team

Teamevent: Burger barbeque at Keramischer OFENBAU

We made good use of the spring weather and barbecued, chatted, and enjoyed a delicious meal and drinks. Really the best way to make use of our garden and Meeting Point! We like to spend our breaks here, but an afternoon of sharing a delicious meal is so much more fun.

Even sinking evening temperatures couldn’t spoil the fun of this awesome and tasty event. Of course, some of our employees also brought their families – that makes team events twice as nice.

Fire not only in the kiln, but also on the grill. With homemade burger buns and sauces and of course with fresh meat from our local butcher – simply delicious! We would all like to thank the organising team for making this great start to the long weekend possible.

Want to be part of an active, motivated, open and diverse team? More information here. Teamevent s like this are not uncommon here – but new ideas are always welcome! A successful company doesn’t just „happen“ – it is formed by its employees. That’s why we are particularly proud to have a committed team that puts its heart and soul into the kiln of the future every day!

We are looking forward to your visit to our LinkedIn profile, getting in contact via and to your application via our application form.

Spring flowerbed in Hildesheim

New spring flowerbed in Hildesheim

Thanks to the efforts of our garden crew, we can now enjoy this beautiful flower bed in our garden. Spring can really have its way with this new garden design and the bees from Hildesheim can also feel at home here.

We are even happier about good weather at the sight of our new flower bed!

Our focus on sustainability does not end in our garden of course. As a kiln manufacturer for ceramic production, we strive to make a decarbonised ceramic industry possible. To achieve this goal, we do not only electrify newly built kiln plants. With our EnerViT H2 ready system, our customers can save energy and emissions immediately by modernising their existing kiln plants. Our technology prepares these plants additionally for up to 100 % hydrogen as soon as the gas is available. This can be achieved in both new and existing plants, preparing them for a decarbonised and sustainable future.

Our Website provides you with more information on our kiln plants and optimisations. Any questions? Get in touch with us at . We discuss current hot topics on our LinkedIn profile as well.

Interested in becoming part of our awesome team and enjoying this flowerbed (among other great benefits)? Find out more about our current vacancies here and apply today! We’re looking forward to interesting discussions and new input.

Kiln from above

What does a Keramischer OFENBAU kiln look from above?

This video of one of our plants under construction shows it impressively!

Kiln from above

Of course, not all kilns look the same – after all, they are individually adapted to all customer requirements. But our industrial kilns have one thing in common: ceramic products such as sanitary ceramics, fuel cells or building ceramics are fired highly efficiently. Whether efficient gas-based or electric production or operation with up to 100 % hydrogen – our kilns can do it!

Would you like to know more about our kilns? Interested in seeing a KOG plant in action? Visit our website and contact us! We not only build new industrial kilns for the ceramic production of tomorrow, we are also experts in the modernisation of existing plants. This is not only about energy savings of up to 50 % and the associated emission reductions. Our modernisations also bring the kilns up to the latest safety standards. For safe and reliable operation in the long term.

Would you like to plan, design or implement the most energy-efficient systems? Then you’ve come to the right place on our careers page. We look forward to receiving your application! If our advertised positions do not match your idea, we also look forward to receiving your speculative application. Also take a look at our LinkedIn profile to see what our team can offer you!

Keramischer OFENBAU – a short film

A picture is worth a thousand words – that’s why we also present ourselves visually!

Corporate film Foreign Trade Award

As the winner of the Lower Saxony Foreign Trade Award 2023, we can do so even better this year: The nomination has earned us a great new image film. A film team accompanied us for a day and shot some great footage.

We do not want to withhold the result of an exciting day of filming with the dedicated novofilm team. That’s how we like to present ourselves! This awesome new imagefilm was brought about by the Lower Saxony Ministry of Economy, Transport, Building and Digitalisation for our nomination for the Lower Saxony Foreign Trade Award. We are very proud of this recognition of our team performance in the past years!

Corporate film Foreign Trade Award

You can find out even more about us here on our website or on our LinkedIn profile – or feel free to contact us! We are your reliable contact for modernisations and new plants for your ceramic production – no one can do energy efficiency as well as we can.

The last time we applied for this award ten years ago, we were already delighted to be nominated for it. A lot has happened since then. But one thing is and remains central to Keramischer OFENBAU: a great, competent and motivated team. This is the only way we have been able to fight our way through the crises of recent years and emerge even stronger internationally.

The Keramischer OFENBAU team really is first class. Would you like to become part of it? Join our award winning team! Check out our careers page for more information on our current vacancies.

Foreign Trade Award for Keramischer OFENBAU!

We won the Lower Saxony Foreign Trade Award!

Yesterday, our managing directors Thomas Alten and Dave McGuinness were presented with the Lower Saxony Foreign Trade Award on behalf of our entire team at the H’Up | Hybrid Event Hub at the HANNOVER MESSE.

„With the Foreign trade award, we honour outstanding companies that are extraordinarily successful on international markets despite global crises.“ This is how Minister Olaf Lies explains the award from Lower Saxony’s Ministry of Economy, Transport, Building and Digitalisation.

Being among the three nominees is already an honour in itself – and above all confirmation of our work over the last few years. 10 years ago, we already applied once and were happy to be nominated. But this year we have taken it one step further. Under the motto „Export success despite permanent crisis“ we have „brought the horse to Hildesheim“ this year.

This makes us very proud, especially after the last few years, marked by global crises! Supply chain problems, travel restrictions, wildly fluctuating price levels in many areas… We have not been spared. But thanks to a great team that has faced every challenge with competence, dedication and flexibility, we are stronger today than ever!

Thank you!

We thank you for all the congratulations and would like to congratulate once again ELEA Technology GmbH and Bergmann Maschinenbau GmbH & Co. KG, who secured a nomination and were rewarded for it with fantastic image films! We also congratulate the nominated large companies Voß Edelstahlhandel GmbH & Co. KG and BLOCK Transformatoren-Elektronik GmbH and the winner of the category Refratechnik Cement GmbH!

What an evening! We are very pleased that we impress with our competence, efficiency and innovation and that our commitment to the sustainable kiln of the future is seen and appreciated.

Many thanks to the jury and the ministry for this honour!

And last but not least: Thank you to our awesome Keramischer OFENBAU team! want to become part of our team? Learn more here.

1111 followers on LinkedIn

1111 followers on #linkedin

Cora Alten from Cologne, responsible for our LinkedIn profile, is especially happy about this number. A big thank you to all those who are interested in Keramischer OFENBAU!

We want to offer insights into our everyday life, our projects and our goals and are therefore very happy about each and every one of you. Competence, efficiency and innovation, these are our strengths and we always have the sustainable kiln of the future in mind. Be it particularly high gas savings, electric heating or hydrogen, whether sanitaryware, tableware, technical or structural ceramics, fuel cells or other products: We engineer the right plant for every need.

And our nomination for the Lower Saxony Foreign Trade Award shows that we are good at it. We are very excited about tomorrow’s Foreign Trade Day at the Hannover Messe and the award ceremony!

Easter Greetings from Keramischer OFENBAU

The Keramischer OFENBAU team wishes you all a wonderful Easter holiday!

We hope that this time with your loved ones is filled with joy, laughter, and plenty of chocolate!

We understand the importance of creativity. Whether it’s a hand painted Easter egg or a unique ceramic piece, the creative process is truly special. That’s why we’re proud to offer high-quality kilns that bring your visions to life. Our highly efficient kilns are not limited to tableware and sanitaryware but will also provide you with the highest quality structural and technical ceramics or even fuel cells. Join us at Keramischer OFENBAU on our way towards the kiln of the future! Our team brings all your ideas to life with your specific needs and maximum efficiency always in mind.

We hope you enjoy your well-deserved Easter break!

You want to become part of our team? We would love to hear from you! Learn more here and here.

Nomination Foreign Trade Award 2023

The nominations for the Lower Saxony Foreign Trade Award 2023 have been announced – and we are in!

We are one of three companies nominated for the Lower Saxony Foreign Trade Award 2023 in the SME category! After the challenges we faced in the past years, we are even more delighted that we were able to convince with our philosophy, our story and our successes.

„Export success despite permanent crisis“ – this is the motto of this year’s Foreign Trade Day, during which the award will be presented. And this motto describes our path over the last few years: despite, or perhaps because of, travel restrictions, supply chain pressures, inflation, price fluctuations, rising energy costs and other challenges, we have been able to prove ourselves and are now stronger than ever.

Our long-standing focus on energy-efficient kilns is now proving to be spot on; with competence, efficiency and innovation, we are in a very good position. Flexibility, creativity and a great team keep us moving forward, further towards the kiln of the future and a more sustainable ceramic industry.

This is also confirmed by the nomination of the expert jury consisting of representatives of the Investitions- und Förderbank Niedersachsen – NBank, NORD/LB, IHK Hannover, NiedersachsenMetall, the Lower Saxony business associations, the state representation of the Lower Saxony chambers of crafts, AGA Unternehmensverband and Deutsche Messe AG under the chairmanship of State Secretary Frank Doods. Many thanks to all involved!

For our customers – and the future!

Internationally, we convince with customised solutions for every need, highest quality thanks to engineering with experience and expertise, close-knit support and maximum reliability. Investing in a Keramischer OFENBAU plant is therefore always a sustainable investment in the future; it enables maximum quality of ceramic production for years and decades. The quality of our plants and our reliable service – that builds trust. And trusting cooperation is part of our recipe for success. Because what is more convincing than really good work?

We approach kiln systems holistically. That’s why we not only build new efficient plants, but also upgrade existing plants. Thanks to EnerViT, up to 50 % emissions can be saved by halving gas consumption. This generates economical kilns that, with EnerViT H2 ready, are even prepared for the complete elimination of fossil fuels.

Nominated – not the first time!

We were already among the lucky nominees in our last application 10 years ago – what an honour to be included again this year. In 2013, we thought about energy efficiency in every project. That has not changed. In the past decade, we have expanded our team, moved, learned a lot and perfected our product. We have never lost sight of the kiln of the future. Also, we have been able to prove several times how flexible, resilient and creative we are in critical times. We countered travel restrictions with AR glasses, supply chain problems with diversification. Of course, we have continued to digitalise, network, overcome challenges and become stronger.

Today, ceramic products are fired in our kilns on five continents in 50 countries. Seven of the top ten producers of sanitary ware use our technology and our great team keeps growing. We can be really proud of this development!

How fantastic that the Lower Saxony Ministry of Economy, Transport, Building and Digitalisation also acknowledges our strengths. We are very much looking forward to the award ceremony on 19 April at the Hannover Messe!

Stay tuned and check our LinkedIn profile for more information!

Our plants are in great demand, so our team really appreciates support. Become part of our success story and apply today!

Trade fair visit in Frankfurt

Trade fair visit in Frankfurt

After a four-year break, we are finally back at the ISH Frankfurt, the International Sanitary and Heating Fair, in Frankfurt this year. You can see Georg von Oldershausen from the Keramischer OFENBAU team at the QUARTER BATH stand by Bartin Seramik and with Kursad Ozkaya from Turkuaz Seramik San. Tic. A.Ş..

Manufacturers of sanitary ceramics are focusing on the energy-efficient and sustainable production of their products today more than ever. The talks at the Frankfurt trade fair show us once again how important our input is in this area. As kiln manufacturers, we can turn the screws that really make production more efficient in the long term.

Starting with the modernisation of existing plants with our EnerViT system – enabling energy savings of up to 50 % – to building new electrically heated kilns, to converting production to using 100 % hydrogen with EnerViT H2 ready: in our portfolio, you will find exactly what you need, and not just as manufacturers of sanitary ceramics.

Interested in more information? Visit us on LinkedIn or contact us directly via !

Do you value personal contact and prioritise customer satisfaction? Join our sales team! You can find out more about our vacancies and our team on our careers page. Please also feel free to contact us at !

A different take on everyday office life: film shooting at Keramischer OFENBAU

Office life with film team

A different take on everyday office life: film shooting at Keramischer OFENBAU

Last week, a film team visited our premises in Hildesheim for a whole day – an exciting day for us! Our team did a great job in front of the camera. We were even able to discover one or two natural talents.

Why film in Hildesheim? That remains our little secret for now. The answer will follow within the next few weeks, so stay tuned and follow us on LinkedIn! Here are a few first insights into this exciting and eventful day at Keramischer OFENBAU in Hildesheim.

Would you like to learn more about us? Visit our website to read about our kiln plants, our team and more. For further insights visit our LinkedIn-Profile! Do you have more questions? You can reach us any time, for example via !

We are not only the market leader in efficient ceramic kilns, but also a really good employer. Our diverse team is open, competent, creative and flexible – and we don’t just say that. You are welcome to visit us to see for yourself.

Are you the perfect fit for the Keramischer OFENBAU team? Take a look at current vacancies on our career page and apply today. We look forward to hearing from you, also at !

The kiln of the future

Kiln of the future

Sustainable ceramics production thanks to Keramischer OFENBAU

We are proud to be part of this project on the way to the most efficient and sustainable production of sanitary ceramics. Our customer has the goal of making ceramic production sustainable and thus future-proof. We are the ideal partner in this endeavour!

With our experience and expertise, we have been convincing our customers for maximum energy efficiency with our EnerViT system for more than a decade. However, we do not rest on our laurels of building the most efficient kilns on the market. EnerViT is always one step ahead: with our technology, this customer’s plants are not only particularly energy-efficient, but they are also ready for a conversion to 100 % hydrogen!

We are now building several kilns for the company that are efficient today and will run on hydrogen tomorrow. Because this is what the ceramics industry of the future looks like: Efficient and independent of fossil fuels. With Keramischer OFENBAU, this change is already taking place today.

We are very much looking forward to the successful cooperation with the RAK Ceramics team! You can read exactly what the project looks like here in our client’s newsletter.

Do you want to make your production sustainable and future-proof? Find more information about our portfolio here or on our LinkedIn profile. Get in contact with us, for example via !

Efficiency – and not only energetic!

Efficient cooperation between Northern Germany and Northern India

Efficiency – the term is not limited to the ever so important energy efficiency for us!

We continuously provide you with insights into our Hildesheim team, but did you know that we work closely with our teams from Keramischer OFENBAU España and Keramischer OFENBAU India?

This allows us to realise projects even more efficiently on site for our customers. Top quality. maximum efficiency, and tailor-made kiln plants – that’s what ceramic producers can expect from us. We build state-of-the-art kilns of highest energy efficiency. And we optimise existing plants for maximum energy savings, depending on our customers‘ needs. With our team in India, our local customers also have a contact person directly at their plant even faster.

We build state-of-the-art kilns with the highest energy efficiency levels and optimise existing plants for maximum energy savings, just as our customers need it. And not just for heating with natural gas – our portfolio ranges from electric heating to operation with 100 % hydrogen. And that for a wide range of applications from tableware, sanitary ware or building ceramics to technical ceramics, fuel cells and battery powder.

A little glimpse of the cooperation between the German and the Indian team: Georg von Oldershausen and Sandeep Mathur on a customer visit and a tunnel kiln resulting from our teamwork in action.

We rely on excellent partnership and intensive exchange to bring the kiln of the future to the whole world. And successfully so!

Many thanks to our Keramischer OFENBAU India team for the close and successful cooperation!

You can find more information on our team here. You are interested in becoming part? Apply now for one of our current vacancies!

Then and now

How time flies!

We have rummaged deep in the photo box and found pictures from the founding days of Keramischer OFENBAU. We simply cannot withhold this picture from you. A lot has changed in the last quarter century, but technology especially, as the comparison between then and now clearly demonstrates. Besides, our team has grown significantly, we moved premises, we’ve convinced more and more customers worldwide and, of course, we have evolved as times changed. You can clearly see the contrast here!

But one thing has not changed: With our kiln systems, we are ahead of the times. State-of-the-art, reliable, adapted to individual requirements and, above all, energy-efficient. Today, this is more convincing than ever!

Eines hat sich aber nicht verändert: Mit unseren Ofenanlagen sind wir der Zeit voraus. Hochmodern, zuverlässig, individuellen Bedarfen angepasst und vor allem energieeffizient. Das überzeugt heute mehr denn je! We are not only the market leader in energy-saving industrial kilns for ceramics, our plants also keep every promise.

On our LinkedIn profile, we introduce ourselves and our products. For example, this roller kiln we built 25 years ago that still reliably fires our customer’s products today. We carry out the modernisations keeping the plants up to date in terms of safety and energy particularly meticulously and efficiently.

Contrast and continuity!

Today, we can continue to offer our customers the best of the best, with many years of experience, always thinking through innovation creatively. That’s why our kiln plants are not only especially efficient, we also build kilns with alternative heating methods. A new electrically heated kiln? The modernisation of an existing kiln for 50 % less gas consumption? Retrofitting our EnerViT system, designed for operation with hydrogen? We are experts for these aims, with a wealth of experience, creativity and the highest level of customer orientation.

More information about us, our products, and our services can be found here or here on our website.

Plus, our top team never says no to reinforcement by new talents. So we look forward to receiving your application for one of our vacancies!

Greetings from Ambiente trade fair

Sales trip: greetings from Ambiente trade fair!

Our salesman Georg von Oldershausen is on the road again. After a joint customer visit with Sandeep Mathur from Keramischer OFENBAU India, he now sends his greetings from the Ambiente trade fair in Frankfurt. Among others, he got to talk to our agent Önder Bozok and Minh Ly, owner of Minh Long I at the fair.

We’re glad that we can travel again and exchange ideas differently and most importantly in person again. Many countries, many faces and one topic: the energy-efficient, state-of-the-art kiln of the future!

A popular topic of interest at the Ambiente: energy efficiency, alternative heating and thus more sustainable production of (tableware) ceramics. We are the ideal partner for this, not only because of our highly efficient EnerViT system. Thanks to EnerViT H2 ready as well. We combine large energy savings at a low threshold with the possibility of replacing emission-intensive natural gas with hydrogen. And this by up to 100 %. More information is available here on our website or via mail at .

You are outgoing and willing to travel, customer-oriented and would like to build the kiln of the future as part of the Keramischer OFENBAU team? Our sales team is looking forward to your support! Find out more about us and your career at Keramischer OFENBAU here.

We’re looking forward to getting in contact with you!

Measures, measures, measures

Measures, meaures, measures for a good energy balance

For a comprehensive energy audit, we need a reliable data basis. Here, our team collects this crucial data in on-site measurements for our customer – with a lot of fun at work, of course!

But why measure before the modernisation of the kiln actually starts?

Such work is particularly important when it comes to optimising the energy efficiency of industrial kilns. How much energy does the plant consume? And how much of it can be saved by installing our EnerViT system for instance? How much waste heat is generated and can thus be put to further use with our heat exchangers? These questions can be answered best on the basis of reliable energy data after careful measurements.

More information on our well-established optimisations of ceramic kilns is available here. Especially our EnerViT system allows for a great potential in energy savings. And we can do even more: With EnerViT H2 ready, your kiln is ready for up to 100 % hydrogen! Feel free to contact us at or visit our LinkedIn profile for more interesting insights.

Our team also welcomes new talent to build the kiln of the future with us. You can find our current job offers and read more about your career at Keramischer OFENBAU here on our website.

Are you interested? Apply directly or send us your documents via mail to .

We’re looking forward to getting in contact!

Did you know… ?

Did you know… ?

Did you know that we built our first roller kiln 25 years ago? Based on our team’s experience, we have gained a lot of experience, constantly developed, and become the market leader in terms of energy efficiency since then. But we also did convincing work a quarter century ago – after all, this first roller kiln of the Keramischer OFENBAU team is still busy producing flower pots and planters today! Of course, energy and safety modernisations were carried out during this time, imperative for reliable and safe operation.

The early trust in us has more than paid off for our customer. That is why this was not the last Keramischer OFENBAU kiln for this company. Their second roller kiln was installed by our team ten years ago.

We offer convincing quality, reliability, and individual service and have been doing so since 1996! In addition, we score points with our focus on the most energy-efficient systems for products of the highest quality – today more important than ever.

You can find more information about our kilns, our modernisations, and services on our website or on LinkedIn. Feel free to additionally contact us at .

Mehr Informationen über unsere Anlagen, Modernisierungen und Services finden Sie auf unserer Website oder auf LinkedIn. Kontaktieren Sie uns zusätzlich gerne über

We also welcome new talent to support our team. Here you can find our current vacancies. Check out our LinkedIn profile for interesting insights and apply today via our application form or mail to .

Walking on thin ice?

Walking on thin ice?

Not at all! Our team will climb your roof in any weather of course! But this time, we can enjoy the best winter weather, with some sunshine even. Greetings from this roof in the snow!

There is however much more to our service than this. That’s why we’re always available for our customers, in any occasion and any weather: Our awesome team supports our customers in all needs, from consultations and trainings to analyses, maintenance, and spare part service.

Do you want to know how our team can improve your kiln plant and support you in the process? You need more information on the Keramischer OFENBAU full service? Here it is!

Sie möchten mehr Informationen zu unserem bewährten Fullservice? Die gibt es hier. You can also contact us directly at . Our customers get reliable, durable and very efficient kilns from us for products of the highest quality. Regular maintenance and repairs by a competent team that knows your kiln inside out also significantly extend its service life. The same applies to on-site training for your own team – the better your employees know the plant, the better they can work with it.

Do you like to think outside the box and overcome challenges in order to deliver optimal results to satisfied customers? Then perhaps have have something here for you in our current vacancies. We always welcome new talent to join our great team and benefit from our experience and expertise. Feel free to visit us on LinkedIn or apply directly via our application form or at .

Modern buildings for modern kilns

Moderne Hallen für moderne Keramiköfen

Thanks to maximum efficiency and state-of-the-art technology, our ceramic kiln plants make a good impression everywhere – whether we built or modernised them.

In such a modern facility however, this kiln also looks really good! This industrial kiln in Thailand does not only look good, but its inner values also score points with maximised output of tableware of the highest quality while reducing energy consumption at the same time. And of course the plant is also state-of-the-art in terms of safety.

This is what you can only get from us: reliable, state-of-the-art and efficient kiln plants, implemented by an open and competent team, optimised for every customer requirement.

This is how we can convince our customers time and time again. More information about our industrial kilns can be found here on our website. But we can also convince our customers with our well-proven full service and, above all, with energy-efficient modernisations using our EnerViT system! You can find more information on our website under Optimisations and Services or contact us directly via . We look forward to hearing from you!

We are also always looking for new talent to join our team! Find out more on our careers page or on our LinkedIn profile. We look forward to receiving your application via the website or by email to .

The Keramischer OFENBAU team wishes you a successful start into the new year 2023!

Talents wanted!

You are looking for exciting tasks in plant engineering? Want to be part of a great, globally operating team? You are interested in building the kiln of the future with us? Then you have come to the right place!

Our company, based in Hildesheim, Germany, specialises in manufacturing industrial kilns for ceramic production worldwide. We are proud of our competence, efficiency and innovation and are looking for talented people to further expand our team. For more than 25 years, we’ve gained experience in building the most energy efficient kilns and would like to share our expertise. Among others, we are looking for support in project management, commissioning, construction, construction, automation and sales.

For more information on our current vacancies, visit our website here. If you would like to gain or already have experience in the areas mentioned and would like to become part of the Keramischer OFENBAU team, we look forward to your application at !

Become part of our dynamic and innovative team, become part of Keramischer OFENBAU!

Especially relevant today: Become an automation technician or programmer at Keramischer OFENBAU! Automation technicians and programmers with team spirit and initiative can expect an exciting and secure job in a great, motivated team and the opportunity to help shape a sustainable future for the ceramics industry worldwide.

We think efficiency innovatively and implement exciting projects with a lot of expertise and experience. And we want to share that! Apply today!

We also welcome you to visit our LinkedIn profile for even more input!

1 000 followers on LinkedIn!

A great start to the year: we’re in four figures!

Keramischer OFENBAU’s profile on LinkedIn has cracked the 1000 follower mark, a great number! We are delighted about the great interest in Insights from Keramischer OFENBAU and would like to thank (over) 1000 followers. In this new year, we will not only present Keramischer OFENBAU as a company on LinkedIn. We make it possible for all followers to get to know our team, our service and our plants better. Because it’s not just our highly efficient and state-of-the-art kiln systems that are convincing!

Whether it’s insights into the work of our team worldwide, information about us as an employer or case studies that show the added value of our work – on LinkedIn we can present ourselves from all sides. So it’s even nicer that so many people are here.

A big thank you from the Keramischer OFENBAU team!

Would you also like to visit us on LinkedIn? You can do so very quickly here! Find additional information on our website, for example about our service or our team. If you would also like to become part of Keramischer OFENBAU, take a look at our current job vacancies and apply today! Our team is always happy to welcome new talents we can drive the development of the ceramics industry towards a more efficient future with.

Heat exchanger for efficient kiln plants

Effective solution for efficient kiln systems

Getting more out of the energy used – That‘s more important today than ever before, in the ceramic industry as well. That’s why we design and build highly efficient industrial kilns for our customers, tailor-made to meet every need. However, a new plant is not always necessary for maximum efficiency. We can also achieve optimal results through energy-efficient modernisation. And at comparatively little expense, for example by retrofitting with heat exchangers.

Our air-water heat exchangers enable the extensive use of exhaust air from cooling processes in continuous kilns and thus offer particular advantages: Besides easy integration into existing processes, particularly high heat transfer and facilitated insulation, a water-based system allows for additional storage of the recovered energy. Our customers can thus further utilise this thermal energy and thus reduce both energy consumption and emissions.

A plant modernised in this way not only becomes more efficient, but can additionally be retrofitted and further optimised later with our EnerViT system – ideally even with EnerViT H2 ready.

Get the best out of your system, use your residual energy! Would you like to learn more about our optimisations and their efficiency? Feel free to contact us and visit our LinkedIn profile. Learn more about us and our performances here! You would like to become part of our awesome team? Find our current vacancies as well as information about Keramischer OFENBAU as your employer here!

Energy efficiency with Keramischer OFENBAU

Energy efficiency with KeramischerOFENBAU

Making more out of the energy consumed – that’s more important today than ever before.

We have prioritised energy efficiency for many years. Therefore, we tailor the most efficient industrial kilns for products of the highest quality for every need. With this, we convinced our long-standing customer Turkuaz Seramik, as this interview starting on page 82 in the Ceramic World Review of Tile Edizioni shows.

More output with less consumption – that’s what our EnerViT system achieves in new plants and the optimisation of existing plants. And not only that. EnerViT H2 ready allows a low-threshold conversion to hydrogen as soon as it is available on site. This article in the ceramic world web newsletter on our EnerViT technology provides more information (and of course pictures).

You would like to commission a new kiln that reliably fires your table- or sanitary ware, your technical or structural ceramics exactly according to your needs? Are savings in energy consumption particularly important to you? Then we are your ideal partner! We engineer and build your plant exactly as you need it. Does your kiln system deserve an optimisation or modernisation to achieve the state of the art not only in terms of safety but also of energy? We are experts in this field! We get the maximum out of your system, in every respect.

Competence, efficiency and innovation, this mixture is what makes us stand out and we are proud of it! We have convinced our long-standing partner Turkuaz Seramik with this more than once.

Find out more about us and our EnerViT system here on our website or contact us directly with any further questions. We look forward to it!

New partner in Turkey

New partner in the new year!

Did you have a good start into this new year of 2023? We sure did!

The strong order book we have built up over the past year is further complemented by our collaboration with Bartin Seramik. We are not the only ones appreciating this cooperation, the customer is impressed as well, as this LinkedIn post shows. Congratulations on the decision for highest energy efficiency in your new tunnel kiln with our EnerViT system!

Our sales expert Georg von Oldershausen held detailed and in-depth talks with @Gürkan Aldatmaz Bay on our behalf in Turkey to offer the ideal kiln for Alvit and Quarter Bath sanitary ceramics. Once the new kiln is in place, it will combine the best quality with maximum efficiency and minimised energy consumption – a really good mix.

The Keramischer OFENBAU team is looking forward to a successful cooperation with our new partner Bartin Seramik! This is what a successful start into the new year looks like.

You can find more about us and our EnerViT system here or via .

Mehr über uns und unser EnerViT-System finden Sie hier oder unter. Feel free to contact us for more information! Would you also like to become part of the Keramischer OFENBAU team and travel the world, for example as a sales engineer, like Georg von Oldershausen? You can find our current vacancies here or here! We are looking forward to getting in contact with you via or via our LinkedIn profile.

2022 with Keramischer OFENBAU

Our annual review 2022

On the last day of the year, we can now look back on a successful year with ups and downs that we have mastered as the great team we are. You don’t go through uncertain times alone, we know that. That’s why we are all the more grateful for the team spirit we have shown in this busy and successful year!

Our MD Dave McGuinness pointed out at the last staff meeting of the year that „the excellent and steady state of the projects up to 2025 is only possible because of our excellent team.“ What an accomplishment after more than two years under Corona conditions!

MD Thomas Alten takes a similar view: „I really see a first class team here, characterised by competence and great commitment. I would like to emphasise the development we have undergone, even through the crisis. We are now stronger than ever! Therefore, we continue to pass on our knowledge and expertise to new talents.“ And our customers would agree, as regular feedback from our partners shows.

We do our job really well, that’s for sure. „I see our strengths not only in our market leadership in efficiency and reliability, but also in development. And I don’t say this lightly – our customers‘ feedback regularly proves it!“ as Thomas Alten puts it. And what would the team be without the captain, the captain without the team and the company without motivating partners and customers?

We can thus be proud of ourselves and look forward to next year!

A Happy New Year from the Keramischer OFENBAU team!

You would also like to become part of our great team? Here and here you can find our current vacancies. Contact us at and visit our LinkedIn profile! We are looking forward to it!

Merry Christmas from the Keramischer OFENBAU team

Christmas greetings: The Keramischer OFENBAU team wishes a merry Christmas!

We are now looking back at an exciting, busy, and especially successful year. The record-level orders in 2022 prove it: We do our job really well. And we can be proud of this. A team working together for such a comeback after challenging corona years really is very valuable. But before we start into the new year, we now enjoy calm and festive Christmas holidays. We wish all our customers, partners, and the whole team happy holidays!

You would like to become part of the fantastic Keramischer OFENBAU team? Look at our current vacancies and get in contact with us at . Our LinkedIn profile can provide you with even more interesting insights. We are looking forward to getting in contact with you! All the best Christmas greetings!

Christmas party a little different

Lying under your desk at the office Christmas party? That’s now part of good manners at Keramischer OFENBAU!

We started off our Christmas party with an office golf tournament, prepared and directed by an expert. Although the parcours in our premises in Hildesheim demanded some flexibility from our five teams and their commanders, we successfully worked our way through, accompanied by lots of laughter. Thus, the following Christmas market style food and drinks were well deserved!

After honours and prizes were awarded, the hard core welcomed the new day again – that’s how it should be! What an awesome and fun evening – thanks to the great preparation by Silvi Tono and all the other hard-working helpers. We are looking forward even more to the next company event next year!

Thank you to the entire Keramischer OFENBAU team for this wonderful Christmas party and fantastic finale to the year! Now we can start into a calm Christmas season and continue to enjoy the last days of the year.

You would like to support our team next year? Check out our current vacancies on our careers page and contact us via email at . We are looking forward to your contact! Do you need an expert in office golf? We can highly recommend this one!

We wish you a wonderful Christmas season!

Bikes for the team at Keramischer OFENBAU

Bikes for the Keramischer OFENBAU team!

„Karma points for fitness and the environment“ is how JobRad puts it.

We are very pleased to be able to offer our team all JobRad benefits from now on! Want to get some exercise before and after work? Anne Zumhasch definitely does and thus gets on her bike every day in wind and weather, heat and cold. And she’s not alone: the Keramischer OFENBAU team is all about cycling. And we want to support that. With JobRad, we finance the bikes of our employees and turn them into company bikes, for private use as well. This is not only good for the environment, but also for our health!

Of course, our IT specialist Stephan Niemeyer didn’t miss out on this opportunity and will ride his new e-mountain bike the 50 kilometres to work – in warmer weather at least! Our sales expert Georg von Oldershausen’s daily commute is a little too long for a bike ride, but the combination of train and bike usually works very well for him. And our managing director @Thomas Alten also regularly get into the pedals for the almost 20-kilometre commute to our Hildesheim premises. These are just some examples of committed colleagues taking their bike for commuting regularly or from time to time.

Bikes for the team – for our health and environment

Every day or every now and then – we are happy about every distance covered with a JobRad by the Keramischer OFENBAU team. For the environment and health!

Of course, Keramischer OFENBAU GmbH does not only score points as an employer with the company bike JobRad. Would you like to find out more about the many benefits our team enjoys or even become part of the Keramischer OFENBAU team? Then take a look at our careers page here and get in contact with us via ! You can find additional information on our LinkedIn profile.

Energetic and safety modernisation

Modernisation of kilns for maximum efficiency and highest safety!

Our competent and experienced team does not only build highly efficient, individual and needs-oriented new industrial kilns: In this picture, an existing plant is put back into operation after extensive modernisation works. Low-threshold conversions thus maximise not only the energy efficiency of the kiln, but also its safety for everyone involved.

Our plants are always state-of-the-art in terms of safety technology – an important requirement for the operation of any industrial kiln. In order to meet the ever higher safety standards, inspections or modernisations are necessary from time to time. Especially benficial in this case: the safety-related retrofit was carried out at the same time as an energetic modernisation. Highest efficiency paired with maximum safety – a great mix for the customer company and its employees!

Our EnerViT system was also able to significantly reduce gas consumption and thus running costs in this plant – despite low-threshold measures. These savings are particularly attractive in times of climate change and rising energy costs.

You can find more information about our optimisations here or via email to. We’d also love to meet you on our LinkedIn profile for interesting insights about completed and ongoing projects!

Are you passionate about energy-efficient and modern kiln systems and would like to become part of a competent, innovative and communicative team? Come and join us! You can find our current vacancies here. We are looking forward to getting in contact with you via !

Service at the highest level

Service at the highest level in Mexico

In Mexico, our colleagues are currently inspecting this tunnel kiln for sanitary ceramics. The concurrent software update additionally benefits our customer. Our service strengthens our customers quickly and individually in every situation. That’s why we send our experienced team all over the world for consultation, installation, and maintenance. Any spare parts needs will also be taken into account in this process. Personal contact is worth its weight in gold here. Individual needs and expectations can best be worked out in a direct conversation on site.

We are grateful for the good cooperation with the customer‘s team. Thank you for the great trust placed in us! Our name stands for competence, efficiency and innovation – a compelling mix. Our implemented projects show: If you expect a particularly energy-efficient and consistently reliable kiln system for products of the highest quality, Keramischer OFENBAU is the right choice. The Keramischer OFENBAU full-service offer significantly extends the lifespan of our reliable industrial kilns.

You would like to know more about our service at the highest level? Find more information here and contact us!

If you want to become part of our awesome team, travel the world and work on intriguing projects with interesting people, look at our current vacancies! You can contact us at our visit us on LinkedIn!

We are looking forward to hearing from you. Best regards from Mexico and Hildesheim!

St. Nicholas at Keramischer OFENBAU

Nicholas greetings from Keramischer OFENBAU!

The Keramischer OFENBAU team wishes all partners, customers and all interested a happy St. Nicholas Day! St. Nicholas has also made it to us, with treats for us in his pocket. We were also already able to enjoy some Christmassy weather in Hildesheim last weekend. So we are very much looking forward to a calm and reflective Christmas season!

Such a great team needs to be celebrated! You would like to become part of our team? Find out more about your career at Keramischer OFENBAU here or on our LinkedIn profile. We are looking forward to getting in contact with you!

Jubilees at Keramischer OFENBAU

Just in time for the beginning of December, we got together with the entire team at our last information event of 2022. Over a snack in our Meeting Point, diverse topics were discussed. Of course, our colleagues in the field or at home also attended online. All on the same page – that’s vital for teamwork throughout the company!

In addition to a summary of the year, current topics and an outlook, the agenda included honouring all those celebrating their anniversary in the team. We are very pleased about their valuable contribution to the success of Keramischer OFENBAU. Congratulations on all your anniversaries!

After Alina B. and Stephan K., who had their 5-year anniversary in August, we honour Katharina E. from the spare parts team on her 15-year anniversary. Inge T. from the design team and Bernd H. from electrical engineering have been part of Keramischer OFENBAU for 25 years. Many thanks for your loyalty and valuable contribution to the company’s success!

We would like to mention once again the jubilees from earlier this year. Maik H., Friedrich O., Barbara S., Jan E. and Anne Z. have been with us for 25 years. They have been part of the company almost from the very beginning!

We are very grateful for the many years of loyalty of these ten team members. Looking forward to the upcoming years together! The Keramischer OFENBAU team wishes you a pleasant start to December. You would like to become part of the Keramischer OFENBAU team? Visit our LinkedIn profile and check out our current vacancies. Contact us at .

Greetings from Indonesia

Greetings from Indonesia!

Georg von Oldershausen from our sales team sends greetings from his customer visit to Indonesia. He travelled to Jakarta and once again had productive discussions with the Director of Vitreous Operations at Kohler Co. Indonesia, Emrah Kaplan. And the feedback is impressive: The customer is highly satisfied with the production in the Keramischer OFENBAU tunnel kiln! We are particularly pleased about such positive feedback. We are very grateful for the trusting cooperation between the teams and look forward to the future together.

Personal contact with our customers is very important to us, as we stand for customised solutions for individual needs. Our experts can give the best advice on site and work out solutions together with our customers. In this way, we can make optimal use of our expertise, competence and experience and respond precisely to our customers‘ wishes when planning our industrial kiln systems. For this purpose, we are happy to travel around the world.

If you would like to learn more about our philosophy, read on here. You are also welcome to visit us on LinkedIn or contact us via .

Would you like to become part of the Keramischer OFENBAU team and travel the world with us? Take a look at our current job vacancies and contact us via .

Students wanted!

Students wanted! At Keramischer OFENBAU, we are actively shaping tomorrow’s ceramics industry today. Therefore, we are always happy to have a breath of fresh air from new bright minds! New ideas are created by sharing our knowledge, creating experts for our research and development, contributing to a more sustainable future. Cooperation with universities and research institutions is thus very important to us as it enables us to actively shape innovation.

The Keramischer OFENBAU team is also always glad to receive student support. Are you still in the middle of your studies and looking for a job? Get in touch with us! Are you about to graduate? If you would like to write your thesis on the topics of SOFCs, hydrogen, energy efficiency or electric heating in the ceramics industry, we look forward to hearing from you! Don’t hesitate to contact us if this does not apply to your profile and plans fully. We strive for new talents in all areas!

You can find more information on a career in the Keramischer OFENBAU team here. Feel free to contact us at or visit our LinkedIn profile for more information on students wanted at Keramischer OFENBAU and many other interesting insights!

Team players wanted at Keramischer OFENBAU!

Team players wanted at Keramischer OFENBAU! Our future-proof solutions continuously impress customers all over the world. That is why we are looking for highly dedicated and motivated support to strengthen our teams in project management, commissioning, construction management, design, procurement and logistics, as well as in sales, project planning, and research and development.

As a technology leader, we actively shape innovation to continuously pursue our sustainable goals. We would like to continue sharing our experience and knowledge with new employees. The experts gained for future-oriented ceramic kiln construction can thus contribute to our development substantially.

„It‘s always been that way“ has had its days long ago: We are looking for bright minds who not only want to further develop our portfolio, but who also want to help shape the interaction, atmosphere and team spirit at Keramischer OFENBAU. Impact through input: New ideas, a breath of fresh air and innovative ideas continue to drive us forward.

Team players wanted at Keramischer OFENBAU! Find our current vacancies here, contact us at or view our profile on LinkedIn!

You fit well into the Keramischer OFENBAU team, but the advertised positions are not ideal for you? Are you studying and would like to write a thesis on the topics of SOFC, hydrogen, energy efficiency or electric heating in the ceramics industry? Would you like to be able to implement your good ideas effectively? We also look forward to hearing from you or receiving your application!

Shubh Deepavali!

Shubh Deepavali

The Keramischer OFENBAU team wishes all our esteemed partners in India a wonderful Diwali 2022!

We hope that this Diwali and its lights will spread all the peace, prosperity, happiness, and health into your life!

Our international network, our partners all over the world, and our team at Keramischer OFENBAU India make us proud everyday.

Congratulations!

Congratulations! We wish Thomas Alten all the best for his special birthday, which we celebrated today with a joint lunch in our Meeting Point. The Keramischer OFENBAU team wishes for many more happy and successful years together!

Would you like to become part of our awesome Keramischer OFENBAU team? Take a look at our job postings or our LinkedIn profile!

There is nothing for you in the advertised positions? Are you studying and would like to write a thesis on the topics of SOFC, hydrogen, energy efficiency or e-heating in the ceramics industry? Would you like to be able to implement your good ideas effectively? Congratulations! We also look forward to hearing from you or receiving your speculative application!

Rising energy prices call for efficient solutions!

We do not only provide our customers with most efficient kilns, but also offer highly effective modernizations for existing plants. Retrofitting our heat exchanger systems for instance allows for the extensive use of exhaust air energy. This energy results from cooling processes in any roller and tunnel kilns. Heat exchangers thus save energy.

Our air-water-heat exchangers allow for specific advantages: Besides their integration into existing processes, their especially high heat transition, and their facilitated isolation, a water based system additionally allows for storage of the recovered energy. This thermal energy can thus be used further, reducing energy consumption and CO2 emissions.

Installing our heat exchangers enables fast savings through more intensive energy use. The exhaust air energy from the cooling processes in tunnel and roller kilns is not released unused. It is further utilised and thus reduces the plant’s energy demand. Therefore, the system is not only more efficient, it allows the kiln plant to be retrofitted with our EnerViT technology at a later date. This means that existing systems can be converted at low cost to reduce emissions and consumption in more efficient kilns. Our heat exchangers combined with our EnerViT system get the best out of your kiln plant, reduce consumption and your energy costs.

Use your residual energy! Contact us if you would like to learn more about energy efficiency through our heat exchanger systems. You can also find information here and on our LinkedIn profile!

Thank you for 888 followers!

888 followers! We now have 888 followers on LinkedIn and counting, thank you from the Keramischer OFENBAU team.

We are pleased with your interest in our team, our projects, and our visions. Are you following us already, getting to know more about us? Thank you so much! You would like to become a follower? Visit us on LinkedIn to learn more about Keramischer OFENBAU! Your would like to become part of our awesome Keramischer OFENBAU team? Check out our vacancies here.

We share interesting insights, input, news, and so much more here and on our LinkedIn profile. Stay tuned for more or get in touch for specific information!

New extended remit for Alexandra Nuss!

After four years in purchasing at Keramischer OFENBAU, Alexandra Nuss has now taken over the coordination and deputy management of our purchasing team. A promotion earned and well-deserved!

Her open and friendly personality is just as valuable in this new position as her great negotiating skills! We hold Alexandra in high regard as a nice member of the Keramischer OFENBAU team and are particularly pleased to have recruited her for this new and expanded area of responsibility.

We are very glad that you take on this new role in strategic and operative purchasing at Keramischer OFENBAU.

Congratulations Alexandra! We are proud that you are part of our team!

Would you also like to become part of our purchasing team or another team at Keramischer OFENBAU? Take a look at our vacancies here or visit our LinkedIn profile. We will implement your ideas and honour your commitment (not only as a promotion earned).

We are also happy to receive your application if our advertised positions do not suit you. Are you studying and about to graduate? You are welcome to contact us if you would like to write your thesis in the fields of SOFC, hydrogen, energy efficiency or e-heating in the ceramics industry with us. You still have some time until graduation and would like to get to know us as an employer? We are always happy to receive initiative applications as a working student at .

Keramischer OFENBAU team starting at the Hildesheim company run!

Running team starting in Hildesheim: We can consider last Friday’s company run a great success!

Our team participated in all three disciplines. They powered their way through different distances during this run, braving the heat. The Keramischer OFENBAU team has taken part in the Hildesheim company run every year since the inception of this great event. We are delighted that it is now possible to hold it again after the Corona break.

As you can see from the happy faces: It was a pleasure for us to participate in this great event again. Not only mental, but also physical fitness has a great added value for each of us. That’s why we are always happy to prepare together for such exciting events in our #Hildesheimat!